Trends in Autonomous Heavy Equipment – Autonomous heavy equipment refers to large machinery and vehicles used in industries such as construction, mining, and agriculture that can operate and perform tasks without human intervention.

These machines are equipped with advanced technologies, sensors, and artificial intelligence systems to navigate, perceive their environment, and carry out various functions autonomously.

The benefits of autonomous heavy equipment include increased productivity, improved efficiency, enhanced safety, and reduced labor costs.

It’s worth noting that the development and adoption of autonomous heavy equipment are ongoing processes, and the level of autonomy can vary.

Types of Autonomous Heavy Equipment

There are several types of autonomous heavy equipment used in various industries. Here are some common examples:

Autonomous Excavators

These are large machines used for digging, lifting, and moving materials.

Autonomous excavators use advanced sensors and computer vision to navigate the terrain, detect obstacles, and perform excavation tasks with precision.

Autonomous Bulldozers

Bulldozers are heavy-duty machines used for pushing and grading soil, rocks, and debris.

Autonomous bulldozers can operate without human intervention, utilizing sensors and GPS to navigate the worksite and carry out tasks efficiently.

Autonomous Loaders

Loaders are commonly used in construction and mining to transport materials, such as soil, gravel, or rocks.

Autonomous loaders can navigate worksites, load and unload materials, and even interact with other autonomous equipment for coordinated operations.

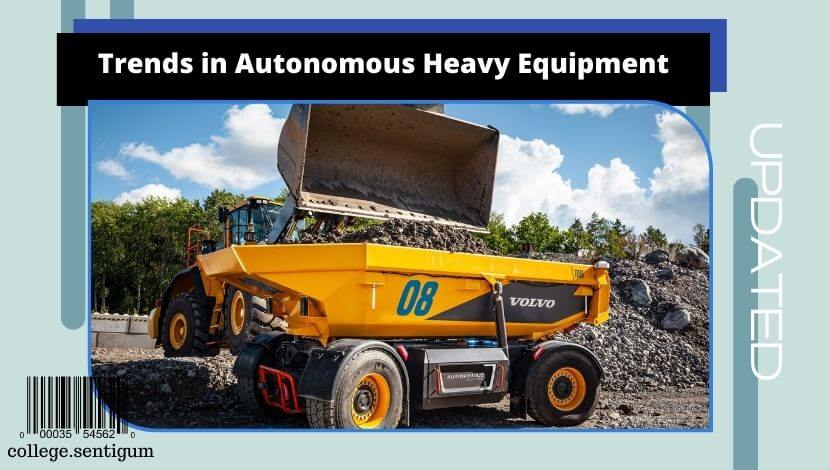

Autonomous Haul Trucks

Haul trucks are massive vehicles used in mining and large-scale construction projects to transport materials over long distances.

Autonomous haul trucks can navigate predefined routes, load and unload materials, and optimize their operations based on real-time data and traffic conditions.

Autonomous Cranes

Cranes are essential for lifting and moving heavy objects in construction and other industries.

Autonomous cranes can perform lifting tasks autonomously, adjusting for load weights, and positioning objects with precision.

Autonomous Drills

In mining and excavation operations, drills are used to create holes for blasting or drilling purposes.

Autonomous drills can be programmed to follow predefined patterns, adjust drilling parameters, and ensure precise and efficient drilling operations.

Autonomous Harvesters

In agriculture, autonomous harvesters are used to gather crops like grains, fruits, or vegetables.

These machines can navigate fields, identify ripe produce, and carry out harvesting operations without the need for manual control.

Autonomous Sprayers

Sprayers are used in agriculture to apply pesticides, herbicides, or fertilizers to crops.

Autonomous sprayers can navigate fields while utilizing sensors and AI algorithms to detect and optimize spray patterns, ensuring precise and efficient application.

These are just a few examples of autonomous heavy equipment, and the range of autonomous machines continues to expand as technology advances.

Each type of equipment is designed to perform specific tasks autonomously, contributing to increased efficiency, safety, and productivity in industries where they are employed.

Read More: Construction Equipment Financing Options Best Loan 2023

Trends in Autonomous Heavy Equipment

Several trends are shaping the development and adoption of autonomous heavy equipment:

Advanced Sensor Technologies

Autonomous heavy equipment relies on various sensors, including LiDAR (Light Detection and Ranging), radar, cameras, and GPS, to perceive and understand their surroundings.

Ongoing advancements in sensor technologies, such as improved range, accuracy, and reliability, enable better perception and decision-making capabilities for autonomous machines.

Artificial Intelligence and Machine Learning

Autonomous heavy equipment utilizes artificial intelligence (AI) and machine learning (ML) algorithms to process sensor data, make real-time decisions, and improve operational efficiency.

AI and ML techniques enable machines to learn from their interactions, optimize performance, and adapt to changing conditions.

Connectivity and Data Exchange

Autonomous heavy equipment can benefit from connectivity and data exchange.

Real-time data transmission between machines, centralized control centers, and cloud platforms allows for remote monitoring, fleet management, and performance optimization.

Additionally, the accumulation and analysis of data from autonomous machines contribute to the development of predictive maintenance and operational insights.

Safety and Collision Avoidance

Safety is a crucial aspect of autonomous heavy equipment.

Continuous advancements in collision detection and avoidance systems, such as object recognition, path planning algorithms, and vehicle-to-vehicle communication, enhance the safety of both the autonomous machines and the people working in their vicinity.

Autonomous Fleets and Coordination

The deployment of multiple autonomous heavy equipment units working collaboratively as a fleet offers increased productivity and efficiency.

Coordinated actions, optimized routes, and synchronized operations among the machines can minimize idle time, improve resource allocation, and enhance overall productivity.

Regulation and Standardization

As autonomous heavy equipment becomes more prevalent, regulations and industry standards are evolving to ensure safety, reliability, and interoperability.

Regulatory frameworks may address issues such as liability, operational guidelines, cybersecurity, and data privacy to promote responsible deployment and operation of autonomous machines.

Hybrid Autonomy and Human-Machine Collaboration

While full autonomy is an ultimate goal, there is a growing trend towards hybrid autonomy, where machines and human operators work together.

Some tasks or situations may still require human expertise, decision-making, or manual intervention.

Hybrid autonomy aims to leverage the strengths of both humans and machines to achieve optimal results.

These trends collectively contribute to the ongoing development and integration of autonomous heavy equipment, enabling industries to enhance productivity, safety, and sustainability in their operations.

Read More: 10 Tips for Renting Heavy Equipment

Conclusion

In conclusion, autonomous heavy equipment represents a significant technological advancement in industries such as construction, mining, and agriculture.

These machines are equipped with advanced sensors, artificial intelligence, and connectivity capabilities, allowing them to operate and perform tasks without direct human intervention.

The ongoing development and adoption of autonomous heavy equipment are driven by various trends, including advancements in sensor technologies, artificial intelligence, connectivity, and safety systems.

These trends contribute to enhanced productivity, improved operational efficiency, and increased safety in industrial operations.

Examples of autonomous heavy equipment include excavators, bulldozers, loaders, haul trucks, cranes, drills, harvesters, and sprayers, among others.

These machines can navigate worksites or fields, carry out tasks with precision, optimize routes and operations, and collaborate with other autonomous machines to achieve higher productivity levels.

While full autonomy is a long-term goal, there is also a trend towards hybrid autonomy, where human operators and machines work together to leverage their respective strengths and expertise.

As technology continues to evolve, regulations and industry standards are being developed to ensure the responsible deployment and operation of autonomous heavy equipment, addressing issues such as safety, liability, and interoperability.

Overall, autonomous heavy equipment holds great potential for industries, offering benefits such as increased productivity, improved efficiency, enhanced safety, and reduced labor costs.

Continued advancements in technology and increased adoption of autonomous machines are expected to drive further innovation and transform industrial operations in the future.